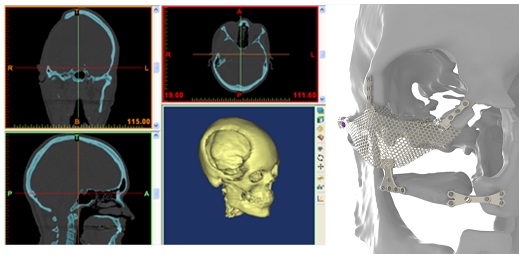

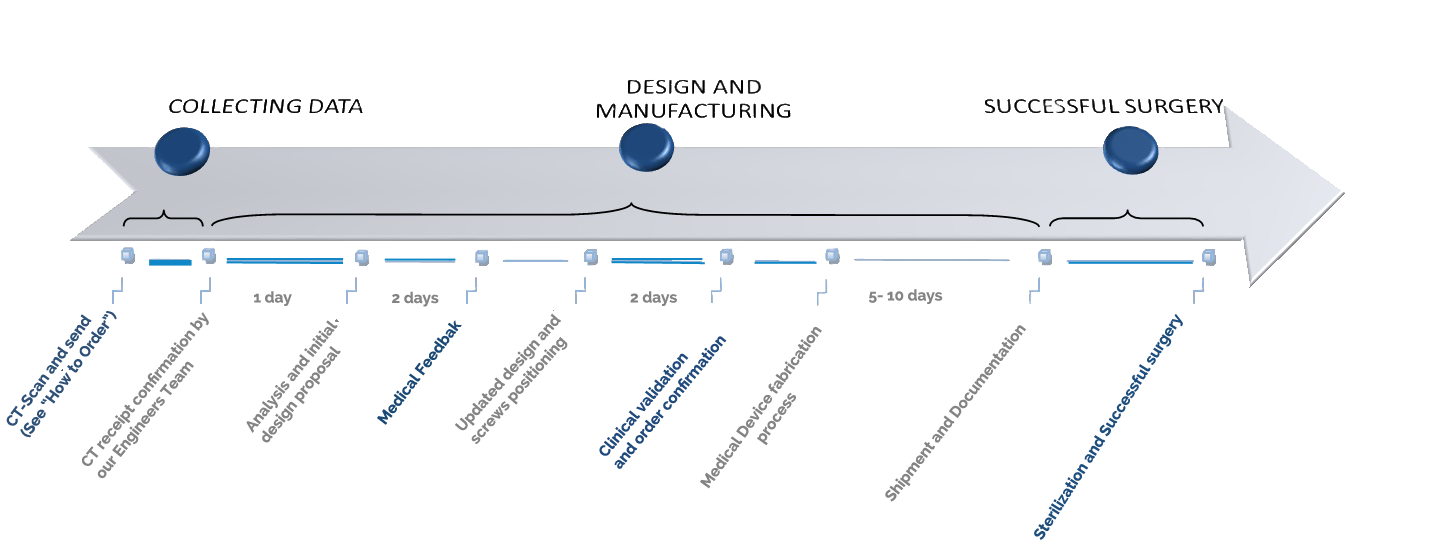

After receiving the medical imaging data, our team of engineers starts its analysis using state of the art software, on which we create a 3D model based on the medical images sent. This 3D model gives us the precise anatomy of the patient and we can tailor made the implant to achieve a device that perfectly fits. The first implant proposal is sent to the healthcare professional for confirmation and screw placement (if needed; i.e. CMF reconstructions). The implant is validated through a software that simulates real life mechanics and studies the behaviour of the implant. The study is then shared with the healthcare professional that gives a final feedback and confirmation. The device is sent to fabrication, and finally is shipped and sterilized to ensure a successful surgery.

We follow a rigorous work flow process in order to unsure the best possible result. Our solutions are not only adapted to the patient but also to the surgeon’s technique and preferred instrumentation.